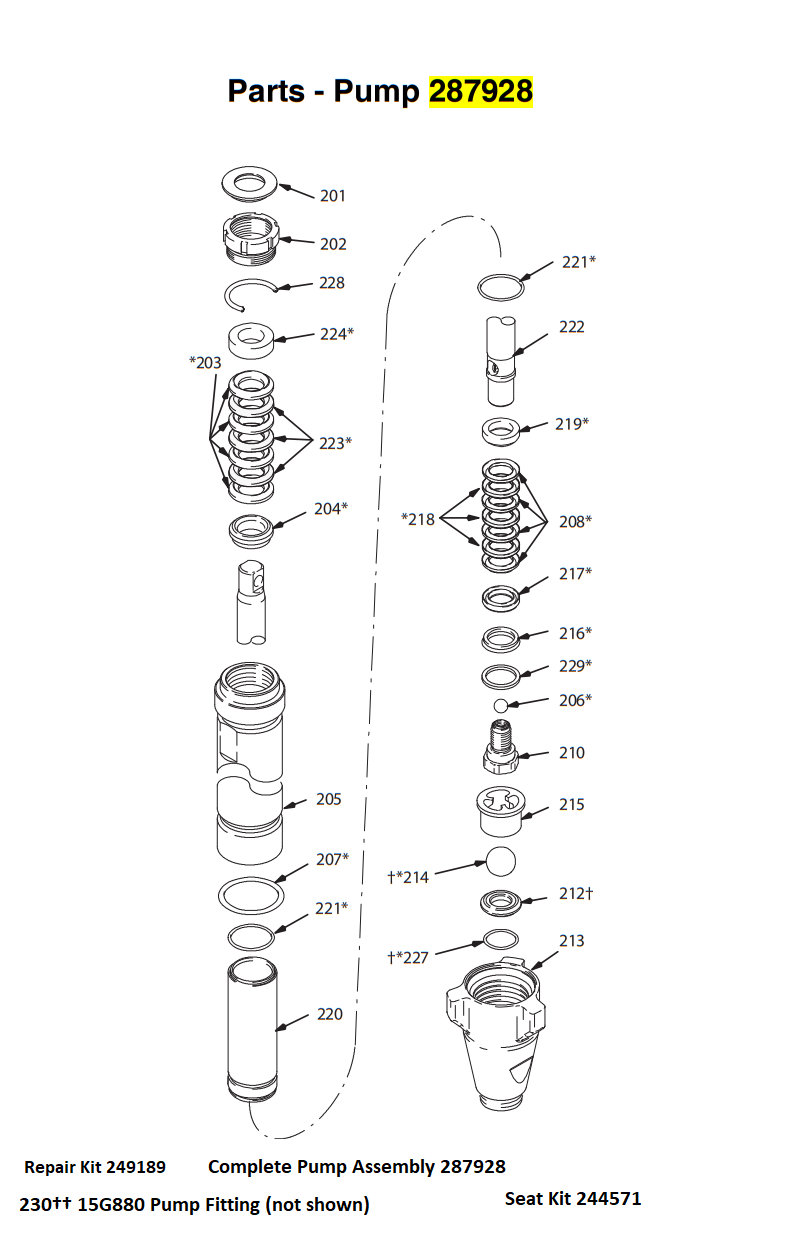

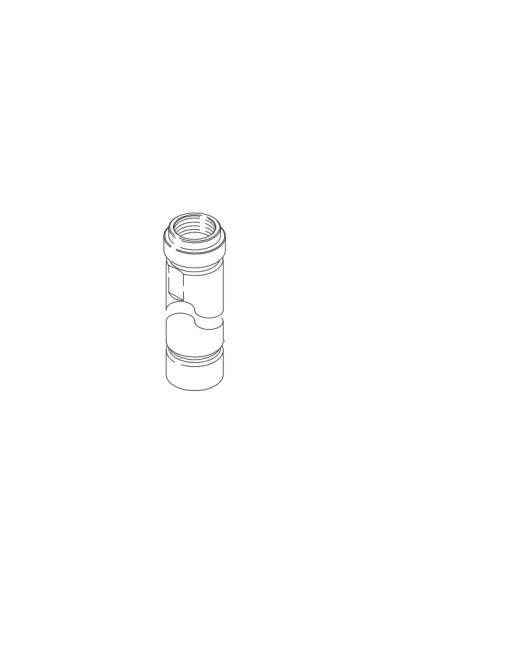

Part Number: 287928

UPC Number: 633955138803

Part Number: 249189

UPC Number: 633955097322

Part Number: 244571

UPC Number: 633955676251

Part Number: 183171

UPC Number: 633955280175

Part Number: 193032

UPC Number: 633955811065

Part Number: 193124

UPC Number: 633955888920

Part Number: 15C989

UPC Number: 633955033443

Part Number: 287581

UPC Number: 633955096981

Part Number: 116327

UPC Number: 633955765238

Part Number: 106556

UPC Number: 633955396784

Part Number: 193125

UPC Number: 633955888937

Part Number: 24U993

UPC Number: 633955684010

Part Number: 196753

UPC Number: 633955732179

Part Number: 111453

UPC Number: 633955483668

Part Number: 196967

UPC Number: 633955967717

Part Number: 118504

UPC Number: 633955048416

Part Number: 183185

UPC Number: 633955632899

Part Number: 15E329

UPC Number: 633955077065

Part Number: 183178

UPC Number: 633955104273

Part Number: 248210

UPC Number: 633955047419

Part Number: 107098

UPC Number: 633955331549

Part Number: 249028

UPC Number: 633955091573

Part Number: 183175

UPC Number: 633955532045

Part Number: 15C990

UPC Number: 633955033504

Part Number: C20987

UPC Number: 633955158719

Part Number: 108526

UPC Number: 633955078024

Part Number: 15C998

UPC Number: 633955033528

Part Number: 15G880

UPC Number: 633955140578

The Graco UltraMax II Mark V is the reliable workhorse in Graco's lineup of graco electric paint sprayer systems. Designed for professionals, it combines high-pressure capacity (up to 3,300 psi), robust frame construction, and easy serviceability. This breakdown dives deep into its pump assembly and related attachments to keep your sprayer performing flawlessly.

At the heart of the UltraMax II Mark V lies a heavy-duty pump, replacement part 248204 for 695/795 units, and 287929 for 1095/Mark V models. The pump comprises key internal components such as piston rods (Part 241008), V-packing seals, piston glands, backup washers, fluid sleeves, and connecting rods

Graco pump repair kits—like the QuikPak Kit 17H839—offer comprehensive sets including V‑packing, bearings, O‑rings, and backup washers. Performing an annual pump rebuild helps prevent drops in pressure, fluid leaks, and costly breakdowns during usage

To safeguard even coverage, these fluid components are essential:

Intake tubes and grooved intake pins

Filter housings with O-rings, diffusion tubes, and caps

30–200 mesh filters, valve seats, piston balls, and drain valves

Keeping these filters clean is vital, especially when using airless paint sprayer attachments or working with additives and higher-viscosity coatings.

The system's structural reliability comes from:

Drive housing and bearing housings (e.g., 240523, 287523)

Electric motor, gears, deflectors, and thrust bearings

Heavy brands: frame assembly, handle bars, pneumatic wheels, leg caps, and fasteners

These support the graco electric paint sprayer’s mobility, vibration resistance, and wear protection. Worn wheels or missing leg caps can make a big job much more difficult.

Though not covering the full control diagram, key electrical parts retain their importance:

Control box, switch housings, terminal posts, potentiometers, rocker switches, grommets, and warning labels

These are crucial for intuitive pressure control and reliable sprayer operation when using graco airless paint sprayer applications.

Your UltraMax II Mark V is supported by these vital components:

Coupled hoses, drain hoses with grooved deflectors

Strainers, quick‑disconnect fittings, and adapter nipples

Spray gun compatibility with graco 395 airless paint sprayer accessories

Graco spray tips like RAC X models & attachments like Blue Guard tip filters

These parts define coverage quality and enable versatility across finishes, textures, and nozzle sizes.

Smaller components often overlooked but imperative:

Retaining clips, hex screws, washers, throttle clips

O‑rings in the pump manifold and fluid housing

Warning and control panel labels—each maintaining safety and compliance

Even tiny clips or missing O‑rings can impact sprayer functionality or compromise performance.

Here’s how to plan maintenance to maximize uptime:

Pump Rebuild (annually or 1,000 hrs)

Replace Piston rod, V‑packing, backup washers, sleeve, and manifold O‑rings using graco pump repair kits.

Filter Service (every 50 hours or per-job)

Rinse or replace filters (30–200 mesh), hoses, diffusion tubes, and strainers.

Spray Gun & Tip Service

Swap out worn graco spray tips, purge gun filters, and check hose fittings.

Frame & Electrical Check

Tighten bolts, inspect wheels and accessories, glaze out wiring harness grommets, inspect switches.

What elevates the UltraMax II Mark V is its compatibility across other Graco tools:

Works seamlessly with the graco 395 airless paint sprayer and Magnum/Mark series attachments

Accepts airless paint sprayer attachments like Blue Guard, JetRoller, and Contractor PC gun upgrades

Flow control, tips, and hoses are often interchangeable between Mark V and Magnum/X5.

Especially useful when pairing with graco electric paint sprayer systems in fleets—it allows shared parts stock and reduces complexity.

| Symptom | Likely Cause | Recommended Repair Item |

|---|---|---|

| Low or fluctuating pressure | Worn packings / seals | Pump kit (e.g., QuikPak or sleeve kit 248209) |

| Leaking fluid | Damaged manifold O‑rings or sleeves | Sleeve kit #248209, manifold packing (108526) |

| Pulsing spray stream | Defective valves or return hose leaks | Valve rebuild kits, drain hose replacement |

| Motor overheating or whining | Worn gears / thrust washers | Drive housing inspection, gear kit replacement |

| Erratic gun spray staining | Contaminated fluid/filter failure | Replace filters, strainers, tip filters |

Proactively handling these signs can save both time and paint.

To maintain accuracy and performance:

Refer to the official graco parts list or exploded diagrams (e.g., Figs. 311362A)

Cross‑reference part numbers exactly—e.g., 287929 pump, 248209 sleeve, 108526 manifold O‑ring.

Add graco pump repair kits, hoses, and graco spray tips to cart with OEM precision.

Include airless paint sprayer attachments like tip filters or roller kits for extended versatility.

Standalone parts ordering ensures proper fit and safeguards warranty integrity.

Exact fit & performance matched to Graco’s original machining specs

Built to handle up to 3,300 psi, especially under heavy loads

Simplified inventory with compatibility across Mark, Magnum, and Ultra lines

Warranty compliance, since aftermarket parts may void coverage

OEM components keep your graco airless paint sprayer, along with airless paint sprayer attachments, operating at peak efficiency across years of jobsite use.

The Graco UltraMax II Mark V is a top-tier, graco electric paint sprayer demanding precise maintenance. This detailed breakdown ensures:

Full pump rebuild use via OEM graco pump repair kits

Clean fluid path with filters, strainers, and hoses

Seamlessness with graco 395 airless paint sprayer and other systems

Sharp, consistent finishes using graco spray tips and control accessories

Easy order-up from the OEM graco parts list to eliminate guesswork

Choose genuine parts, perform upkeep strategically, and your Mark V will prove a dependable partner in delivering pro‑grade finishes—project after project.

Keep your UltraMax II Mark V ready for any challenge: use OEM replacements, adhere to service intervals, and order parts before any issues show. That’s the pro way to get the best performance—always.

Subscribe to our newsletter to get exclusive discounts and new theme launches right in your inbox.

You may unsubscribe at any moment. For that purpose, please find our contact info in the legal notice.

![]()

![]()

![]()

![]()